One of the production areas of the enterprise (ROSNAMIS LLC) is wear-resistant bimetallic plates RTP

RTP bimetallic plates are two-layer metal sheets made of low-carbon or heat-resistant steel, with dimensions of 1500x3000 mm and 2000x3000 mm.

In bimetallic plates, the layers have different functions and are called the main and deposited layer. The main layer takes on mechanical loads, the deposited layer has high wear resistance and performs a protective function.

The thickness of the base and deposited layer can be different, depending on the requirements of the customer’s technical specifications.

Wear-resistant RTP plates are overlaid with powder surfacing strips of our own production, with a cross-section of 16.5 x 4 mm and 10 x 3 mm (depending on the thickness of the original steel sheet). The fill factor of flux-cored strips ranges from 55 to 62%. Therefore, when surfacing with flux-cored strips it is possible to achieve the required carbon and chromium contents already in the first layer, which ensures a stable microstructure of the deposited metal. This fact makes it possible to obtain wear-resistant plates with significantly improved consumer properties.

Currently, bimetallic plates are used in many industries - metallurgical, mining, woodworking, glass, chemical, cement, energy, agricultural, etc. – wherever there is erosion and severe abrasive wear.

Application examples – loader buckets, vibrating units, excavator buckets, heavy-duty dump truck bodies, pipelines, mills, crushers, screens, cyclone catchers, chutes, bunkers, transfer devices, sorting devices, fans, filling devices, sieves, mixers, transport boxes, pipes, etc.

RTP boards can be cut to size using plasma, laser or waterjet cutting. As a general rule, you should always cut from the base layer side to prevent molten reinforcement alloy from penetrating into the base material, making welding difficult. However, when waterjet cutting a slab, this must be done from the side of the deposited layer.

The great advantage of bimetallic plates is the ability to manufacture finished products from them of almost any shape according to customer drawings, taking into account rolling and bending.

On surfaces that need to be protected from wear, parts made from RTP plates are easily mounted by welding or with special bolts or studs.

Feasibility of using RTP bimetallic plates:

- possibility of protecting large surfaces from various types of wear;

- increasing the service life of equipment by increasing the wear resistance of the protected surface;

- reducing the weight of the lining by up to 50%, which increases equipment productivity;

- no long production downtime;

- no need to purchase new expensive equipment;

- reducing costs for special repair teams;

- reducing maintenance and repair costs;

- reduction of operating costs for equipment maintenance, which entails a reduction in production costs;

- simplicity of the installation process of bimetallic plates.

Brands of bimetallic plates commercially produced by our company:

RTP 214

Bimetallic wear-resistant plate, operating in conditions requiring high wear resistance, with moderate shock loads. Due to its technological properties, it is the most popular for use in many industries.

|

Элемент |

C |

Cr |

Fe |

Mn |

прочее |

HRC |

|

% |

5,2 |

35,0 |

ост. |

2,0 |

1,5 |

60-65 |

RTP 178

Bimetallic wear-resistant plate with increased resistance to abrasive and erosive wear. The deposited layer of complex carbides is distinguished by a high density of solid particles and allows working under conditions of abrasive and gas-abrasive wear at normal and elevated temperatures.

|

Element |

C |

Cr |

Mn |

Si |

В |

Nb |

Fe |

HRC |

|

% |

5,4 |

21,0 |

0,3 |

1,5 |

1,0 |

6,0 |

ост. |

60-65 |

RTP 179

Bimetallic plate for use in parts and components of equipment operating under conditions of high abrasion at high temperatures up to 755 ° C with moderate shock loads.

|

Element |

C |

Cr |

Si |

Mo |

W |

Nb |

Fe |

V |

Прочее |

HRC |

|

% |

5,0 |

23,0 |

2,0 |

6,0 |

1,5 |

6,0 |

ост. |

1,0 |

1,3 |

> 55 |

RTP 101

Bimetallic plate for equipment operating under conditions of intense abrasive and gas-abrasive wear with moderate shock loads

|

Element |

C |

Cr |

Ni |

Fe |

Si |

Mn |

Прочее |

HRC |

|

% |

3,0 |

25,0 |

2,0 |

ост. |

3,0 |

3,0 |

1,2 |

50-56 |

RTP 180

Bimetallic plate for machine parts and mechanisms operating under conditions of intense abrasive and gas-abrasive wear with moderate shock loads

|

Element |

C |

Cr |

Mo |

Fe |

Si |

Прочее |

HRC |

|

% |

5,0 |

34,0 |

2,0 |

ост. |

1,0 |

2,2 |

58-62 |

RTP 111

Bimetallic plate with a deposited layer of nickel-carbide-chromium alloy. For parts operating under conditions of abrasive and gas-abrasive types of wear, at normal and elevated temperatures.p>

|

Element |

C |

Cr |

Ni |

Mn |

Si |

Прочее |

HRC |

|

% |

5,0 |

40,0 |

40,0 |

1,0 |

2,0 |

1,0 |

50-56 |

* Typical ratios of the base and deposited layer in RTP bimetallic plates:

|

|

Thickness of deposited layer, mm |

|||||||

|

Base thickness, mm |

|

2 |

4 |

5 |

7 |

9 |

13 |

17 |

|

5 |

Х |

Х |

|

|

|

|

|

|

|

6 |

Х |

Х |

Х |

|

|

|

|

|

|

8 |

|

Х |

Х |

Х |

|

|

|

|

|

10 |

|

|

Х |

|

Х |

Х |

|

|

|

12 |

|

|

Х |

|

Х |

Х |

Х |

|

|

16 |

|

|

Х |

|

Х |

Х |

|

|

|

|

20 |

|

Х |

Х |

|

Х |

Х |

|

* Changing the ratios is possible according to the customer’s technical specifications

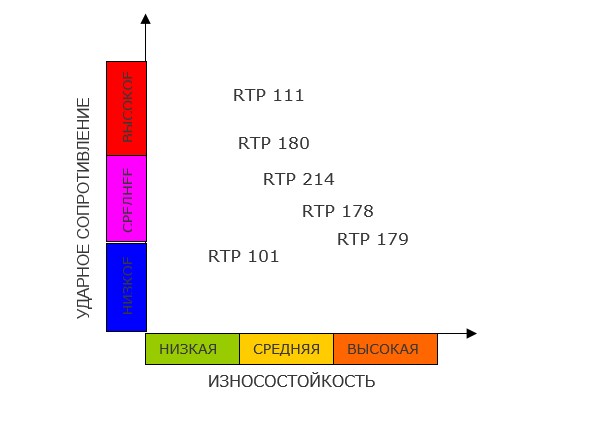

Durability chart for RTP bimetallic plates

To all of the above, I would like to add that we guarantee the high quality of the RTP bimetallic plates we produce, at a fairly low competitive price, achieved through the use of exclusively our own surfacing materials and alloys.